Main Classification of Semiconductor Materials

Sep 28, 2023

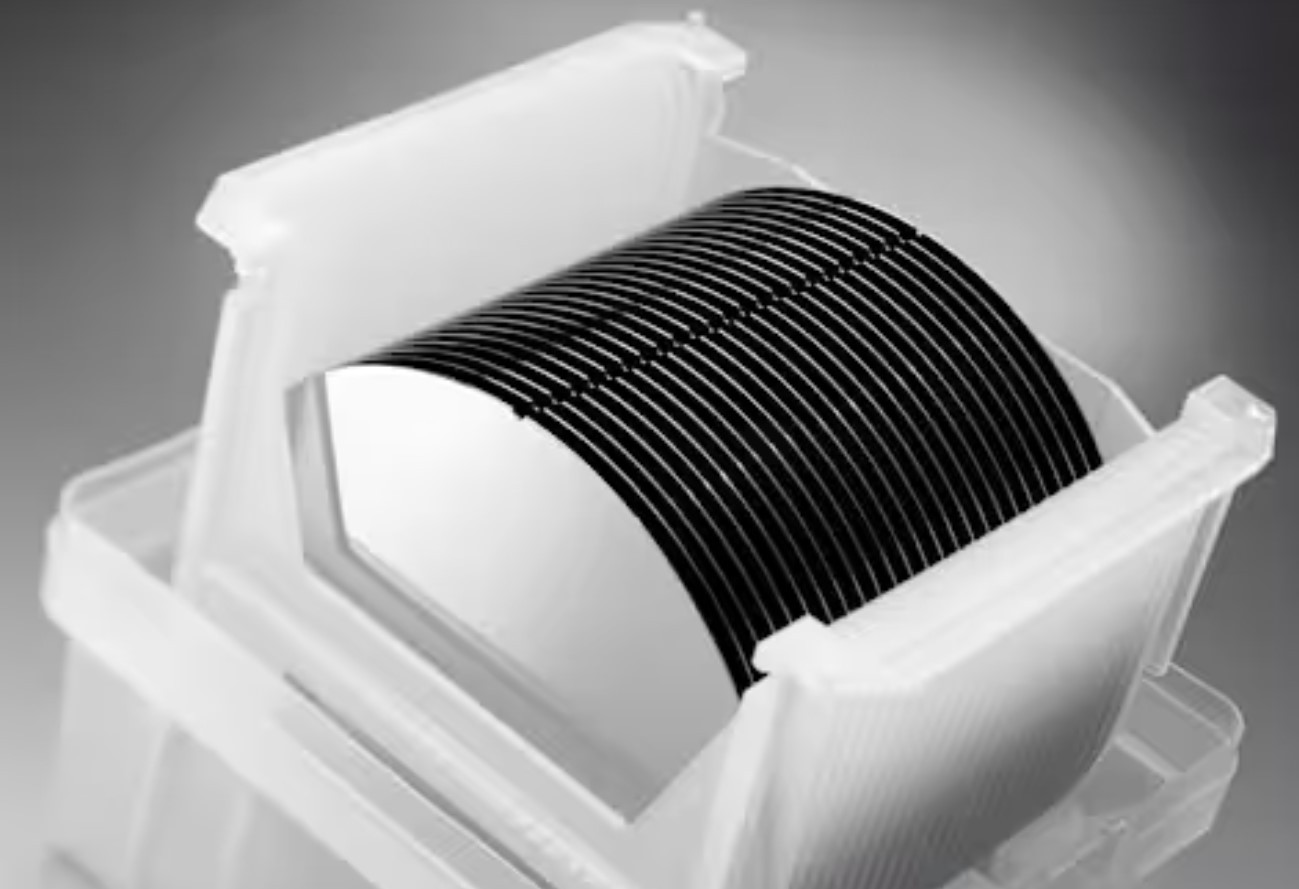

Semiconductor materials are divided according to application links and can be divided into two categories: front-end wafer manufacturing materials and back-end packaging materials. The main wafer manufacturing materials include: silicon wafers, electronic special gases, photoresists and supporting reagents, wet electronic chemicals, polishing materials, targets, photomasks, etc.; the main packaging materials include: lead frames, packaging substrates , plastic sealing materials, ceramic materials, bonding wires, cutting materials, etc.

Proportion of various materials:

Among semiconductor materials, manufacturing materials account for approximately 63.1%, and packaging materials account for 36.9%;

Among wafer manufacturing materials, silicon wafers account for the highest proportion, accounting for 35%; electronic gas ranks second, accounting for 13%; masks rank third, accounting for 12%, and photoresist accounts for 6%; photoresist ranks third Supporting materials account for 8%; wet electronic chemicals account for 7%; CMP polishing materials account for 6%; target materials account for 2%.

Among packaging materials, packaging substrates account for the highest proportion at 48%; lead frames, bonding wires, packaging materials, ceramic substrates, and chip bonding materials account for 15%, 15%, 10%, 6%, and 3% .

![]() Network Supported

Network Supported